Patterson Whittaker Architectural Profiles Crafts Custom Architectural Foam Shapes Out of Reinforced Cement Coated EPS for High End Construction With Easier Installation

In the competitive world of modern construction, Patterson Whittaker Architectural Profiles has emerged as the favorite choice for contractors across the United States and Canada, specifically for its specialization in EPS architectural foam shapes.

Custom crafted, coated in reinforced cement, and available with short lead times, Patterson Whittaker has been able to create durable, long lasting products that combine the versatility and quality of other supposedly “high end” materials like wood, precast concrete, and GFRC, and replaced them with a product that is shockingly lightweight, faster to design, and so much more – all for a total project price that is typically a fraction of competing materials.

EPS acts as an architectural design solution that offers both contractors and architects the freedom to innovate and the ability to install unique designs with ease on the exterior AND interior of a property. Our support team is more than happy to meet with you to discuss different products you can create. If you would like to learn more about these shapes, please fill out our online form for an estimate or call 206.953.5209 in the United States or 604.285.6550 in Canada.

What is EPS – And Why is It Used for Architectural Shapes?

Expanded Polystyrene (EPS) architectural foam shapes, also just called “architectural foam” or “EPS shapes,” is a lightweight form of plastic. Most people know EPS as Styrofoam™, but in the architectural world, EPS provides a far more complex, far more versatile solution to your design ideas and challenges.

When EPS is coated in reinforced cement, it is capable of everything from basic structural forms to intricate decorative elements, providing architects and builders with a versatile tool for both practical and creative uses.

When compared with traditional construction materials, EPS stands out for its unique properties. It is

- Significantly lighter than materials like concrete or metal, making it easier to transport and install, and it puts less stress on the building’s structure.

- Durable. EPS architectural foam shapes hold up well against moisture absorption and decay, issues commonly associated with wood. While not as inherently durable as concrete or stone, EPS’s resilience is greatly enhanced when coated with our reinforced cement, making it suitable for a wide range of architectural applications.

- Profoundly easy to install. In fact, the cement coated EPS, despite its durability, is so light weight that the products themselves can frequently be glued on the property with contractors glue while still looking incredibly elegant.

EPS foam shapes are a versatile high end product that has the ease and total project cost of more economic options.

One of the standout features of EPS is its excellent insulation properties. It effectively reduces the need for additional insulating materials, contributing to the energy efficiency of buildings. This is a stark contrast to materials like concrete, which, despite their strength, have poor insulation properties.

Benefits of Reinforced Cement Coated EPS

Reinforcing EPS with a cement coating brings several advantages, transforming it into a material well-suited for high-end construction. The cement coating significantly enhances the durability of EPS, protecting it from physical damage and environmental factors such as UV radiation. This makes it ideal for exterior applications where exposure to the elements is a concern.

The weather resistance of cement-coated EPS is another key benefit. It stands up well against various climates, safeguarding buildings from moisture, wind, and temperature fluctuations. This resilience is particularly valuable in areas with harsh weather conditions.

Aesthetically, cement-coated EPS offers a lot of flexibility. It can be finished to mimic other materials like stone, wood, or concrete, fitting seamlessly into any architectural style. The ability to paint, texture, or design it according to specific aesthetic requirements makes it a favorite among architects and designers.

From an environmental perspective, reinforced cement-coated EPS has its advantages. The combination of EPS’s lightweight nature and the strength of cement reduces the overall carbon footprint of construction materials. This is because less energy is needed for their transportation and installation. Moreover, the insulating properties of EPS contribute to the energy efficiency of buildings, which is a boon in terms of reducing heating and cooling costs and overall energy consumption.

Overall, reinforced cement-coated EPS architectural foam shapes offer an excellent balance between lightweight, durability, and versatility. They adapt well to various environmental conditions and are increasingly favored in modern construction, especially in high-end projects where functionality and design are equally important.

Customization Capabilities of Patterson Whittaker

Patterson Whittaker Architectural Profiles stands out in the construction industry for its exceptional ability to customize EPS architectural foam shapes. This flexibility allows architects and designers to realize their visions in both commercial and high-end residential properties.

Customization Process

The customization process at Patterson Whittaker is a fusion of client collaboration and technical expertise. Clients bring their concepts, often unique and complex, and Patterson Whittaker’s team works closely with them to transform these ideas into feasible designs.

The process involves several stages, including initial design consultations, 3D modeling, and prototype development, ensuring that the final product aligns perfectly with the client’s vision and the project’s specific architectural requirements. However, the process to customize your designs is significantly less intensive than other products, like GFRC, which typically require molds (adding to the costs) and far longer lead times.

Types of Custom Designs

Patterson Whittaker’s capabilities in creating custom EPS architectural shapes are vast and varied, as we are essentially able to design anything that you envision. Some of the types of products that can be created include:

- Decorative Elements – Customized moldings, cornices, columns, and capitals that add a unique aesthetic to buildings.

- Structural Components – Tailored EPS foam shapes for structural applications, such as lightweight beams or panels that are both functional and decorative.

- Facade Elements – Customized façade elements, including window surrounds, door arches, and wall accents, which enhance the exterior appearance of buildings.

- Specialized Architectural Features – Unique features like dome ceilings, custom-designed archways, or intricate sculptural elements for both interior and exterior applications.

Although architectural EPS shapes have no structural benefits, they also are one of the only products that – since they do not typically require any manual reinforcement – will not break the waterproof barrier of the property. This not only makes installation easier, but opens the door for this product to be placed on surfaces of any material.

Technological Innovations in EPS Manufacturing

Patterson Whittaker is at the forefront of incorporating cutting-edge technology into the manufacturing of EPS architectural shapes.

- Advanced CNC Cutting Machines – These machines allow for precise cutting of EPS foam, ensuring that even the most intricate designs are accurately produced.

- 3D Printing and Modeling – Utilizing 3D printing technology for prototypes and complex shapes, providing clients with a tangible preview of the final product.

- Automated Coating Systems – Ensuring uniform application of reinforced cement coating, which is crucial for both durability and aesthetic appeal.

The integration of these technologies allows Patterson Whittaker to not only maintain high precision in their custom designs but also enhance production efficiency. This technological edge translates into the creation of complex shapes with high accuracy, meeting the specific demands of each project.

Fast Lead Times from Patterson Whittaker

These are all some of the many benefits of choosing EPS foam shapes for your next product, but while architectural EPS does have many benefits, our team at Patterson Whittaker provides even more. We believe it is important to make sure every product is completed with fast lead times to help you manage your project.

Our efficient process provides you with the ability to produce and deliver custom EPS shapes quickly means that project managers can maintain or even accelerate construction schedules. This efficiency is particularly valuable in commercial construction where delays can have significant financial implications.

Ease of Installation for Architectural Foam

One of the most significant advantages of EPS architectural foam shapes is their lightweight nature, making them much easier to handle and install compared to traditional building materials. This quality not only speeds up the installation process but also reduces the labor intensity and overall cost of installation.

When compared to heavier materials like stone or metal, EPS shapes require less structural support and can be installed with greater ease and speed. The simplicity of installation becomes a crucial factor in high-end construction projects, where precision and time are of the essence.

Patterson Whittaker’s approach not only meets the aesthetic and functional requirements of modern construction but also contributes to more efficient and effective project management.

Applications in High-End Construction

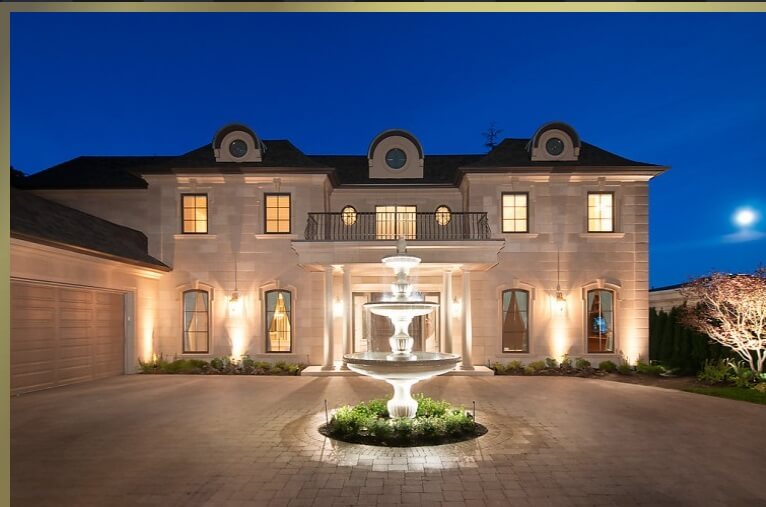

Patterson Whittaker’s EPS architectural foam shapes have carved a niche in high-end construction, transforming how luxury buildings are both designed and perceived. These foam shapes are not just decorative elements; they contribute significantly to the aesthetic integrity of sophisticated construction projects.

In the realm of high-end construction, where every detail matters, Patterson Whittaker’s products have been used to enhance exterior facades, lending them a unique and striking appearance. These shapes allow for intricate designs that were once difficult to achieve, making them a favorite among architects working on luxury commercial and residential buildings.

Inside these upscale properties, the versatility of EPS shapes becomes evident in the form of customized interior design elements. From elegant moldings to ornate ceiling medallions and bespoke columns, these products add a level of refinement that defines premium spaces. Beyond their visual appeal, these architectural foam shapes contribute to the functionality of buildings, particularly in terms of insulation. Their thermal insulation properties play a crucial role in energy efficiency, a key aspect of modern luxury construction.

Sustainability and Environmental Considerations

The sustainability aspect of using EPS in construction has been a point of focus for Patterson Whittaker. Recognizing the environmental implications of construction materials, the company has dedicated efforts to ensure that their EPS products are not just efficient but also eco-friendly. A significant part of this initiative involves the recyclability of EPS. Patterson Whittaker champions the recycling and responsible disposal of EPS, mitigating the environmental impact commonly associated with plastic-based products.

Moreover, the company’s commitment to sustainability is evident in their manufacturing processes. Striving to minimize the ecological footprint, Patterson Whittaker employs sustainable practices in the production of their EPS shapes. These practices, coupled with the inherent energy-saving properties of EPS due to its insulation capabilities, align with the growing global emphasis on environmentally responsible construction.

Future of EPS in Construction

Looking ahead, the future of EPS in construction, particularly in high-end projects, seems bright and promising. As the industry continues to evolve, the demand for versatile, efficient, and sustainable building materials is expected to rise.

Patterson Whittaker is poised to meet this demand, continually innovating and adapting to the changing landscape of construction technology. The company is actively exploring new advancements in EPS technology, aiming to enhance the functionality and environmental sustainability of their products. This forward-thinking approach is likely to keep them at the forefront of the construction materials sector, especially as more builders and architects seek out innovative solutions for luxury projects.

Get Started Today with EPS Architectural Foam Shapes from Patterson Whittaker

Patterson Whittaker’s custom EPS architectural foam shapes represent a significant advancement in high-end construction. We have blended innovation, functionality, and aesthetic appeal in our products, making a notable impact on the construction industry.

As Patterson Whittaker continues to innovate and evolve, our role in shaping the future of luxury construction remains both vital and promising. Our products are not just building materials – they are a testament to our company’s dedication to advancing construction technology. Learn more about Patterson Whittaker or get started by contacting us today via our online form.

Recent Comments